Controller Systems 251213-01

Document ID: 251213-01

Title: STEWARD Controller Systems & Industrial IoT Architecture

Author: Comfac Corporation

Date: December 13, 2025

Status: Internal Strategy / Pre-Release (Open Source Target: Q1 2026)

STEWARD Controller Systems: Industrial IoT Architecture

1. Executive Summary: The STEWARD Concept

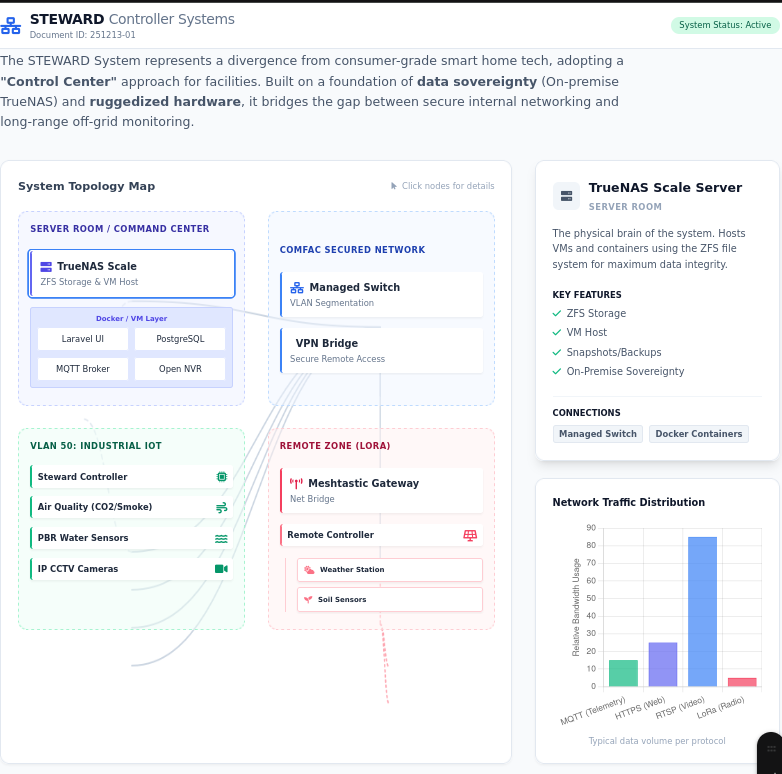

The STEWARD System is Comfac Corporation’s facility management platform. While inspired by the modularity of Home Assistant, STEWARD diverges significantly to address the rigorous demands of Data Centers, Command Centers, and Industrial Resource Management.

Unlike consumer-grade smart home systems, STEWARD adopts the "Control Center" approach: centralized visibility, ruggedized edge hardware, and mission-critical reliability. It relies on a robust stack of MQTT for real-time messaging, PostgreSQL for historical data warehousing, and Laravel for complex business logic and user interface.

Open Source Roadmap:

Currently under active internal development, Comfac aims to release the core STEWARD software stack as Open Source on GitHub in Q1 2026. The project will be licensed under GPLv3 to encourage community contribution while ensuring that improvements remain free for the industrial ecosystem.

2. Network Architecture & Connectivity

The STEWARD network is designed for security and range, utilizing a hybrid of standard IP networking and Long-Range Radio (LoRa).

2.1 The Backbone: MQTT & VPN-Bridge

MQTT (Message Queuing Telemetry Transport) is the central nervous system of STEWARD. Every sensor, relay, and controller publishes and subscribes to topics here.

To secure these devices:

- VLAN Isolation: All IoT devices (Espressif controllers, cameras, sensors) reside on a dedicated IoT VLAN that has no direct access to the internet.

- VPN-Bridge: A secure VPN Bridge allows the STEWARD Server (and authorized remote engineers) to tunnel into this VLAN safely. This eliminates the need to expose insecure IoT ports to the web.

2.2 Extending the Reach: Meshtastic & LoRa

In large facilities (e.g., agricultural zones, sprawling campuses), running fiber or point-to-point WiFi for a simple temperature sensor is cost-prohibitive.

- Solution: We utilize Meshtastic (LoRa) networks.

- Function: Remote sensors transmit log data (short bits of text/JSON) over kilometers using low-frequency radio (433MHz/868MHz/915MHz) to a central Gateway Node.

- Power Autonomy: These remote nodes are designed as self-contained, off-grid units. They rely on LiFePO4 battery banks harvested via integrated Solar Panels or Micro-Wind Turbines, ensuring continuous operation even in areas without utility power.

- Benefit: Connects sensors kilometers away without expensive Ubiquiti airFiber links or trenching for cables.

3. Hardware Philosophy: The Comfac Standard

3.1 The "Torture Tested" Design

Industrial centralization requires reducing the points of failure. Comfac designs are "Torture Tested":

- Thermal Management: Our enclosures feature oversized heat sinks and active cooling fans, designed specifically for the Philippine tropical climate.

- Rugged Housing: We utilize larger, robust enclosures rather than sleek, compact consumer plastics. We prioritize airflow and durability over aesthetics.

- Manual Override: A non-negotiable Comfac standard. All automated relays include physical manual switches. While this increases upfront manufacturing costs, it lowers Total Cost of Ownership (TCO) by ensuring operations can continue manually during digital failures, preventing costly downtime.

3.2 The Shift: From Arduino to Espressif

Note: Following the market shifts regarding Qualcomm’s acquisition strategies and the changing landscape of the Arduino ecosystem, Comfac has migrated its core development away from standard Arduino hardware.

- Current Standard: We focus on Espressif (ESP32/S3/C3) chips and Adafruit ecosystems.

- Why Espressif? It represents the pinnacle of "Chinese Open Source" hardware—high performance, integrated WiFi/Bluetooth, dual-core processing, and massive community support at a price point that makes widespread industrial deployment feasible.

3.3 Sustainability & Right-to-Repair

We leverage the Philippines' specialization in semiconductors and electronics assembly.

- Local Sourcing: By manufacturing and sourcing parts locally, we drastically reduce our GHG footprint compared to importing finished goods.

- Open Source Ecology: Our designs utilize off-the-shelf components. We adhere to Right-to-Repair principles. A remote facility manager can replace a standard relay or fan in our unit without waiting for a proprietary part to ship from overseas.

- No Logistical Friction: Comfac integrates these disparate open-source solutions into a consolidated ecosystem, providing the support layer that open-source projects typically lack.

4. The Controller & Sensor Portfolio

4.1 Industrial Controllers

Built on the ESP32 platform, these DIN-rail mountable units serve as the "Twigs" of the system (see Document 251213-PDT). They handle local logic, ensuring that if the Server goes down, the local machine safety protocols remain active.

4.2 Environmental Sensors

- Airflow: Validated via FreeCAD CFD (Computational Fluid Dynamics) analysis to ensure optimal placement and reading accuracy within ducts and server racks.

- Air Quality: MQTT-native sensors for CO2 and Smoke detection, critical for early fire warning in data centers.

- Temp/Humidity: High-precision DHT/SHT sensors for HVAC optimization.

4.3 Water Quality (PBR Systems)

Designed specifically for Photobioreactor (PBR) and aquaculture management:

- Parameters: Dissolved CO2, Water Temperature, and Pump Current monitoring.

- Integration: These feed directly into the automation logic to adjust aeration and nutrient dosing.

4.4 Advanced Vision & Depth

- CCTV: We utilize standard IP Cameras feeding into Open Source NVRs (Network Video Recorders).

- Lidar: Used for privacy-preserving object detection and depth monitoring (e.g., volume of biomass in a tank, or people-counting in a secure zone without facial recognition).

5. Infrastructure: The TrueNAS Backbone

The physical brain of the STEWARD system runs on TrueNAS Scale.

- Hardware: ranges from low-powered SoCs (for edge nodes) to beefy Rackmount Servers (for central command).

- Virtualization: TrueNAS hosts the Virtual Machines (VMs) and Docker Containers for:

- The Laravel/Postgres Web Server.

- The MQTT Broker (Mosquitto/EMQX).

- The NVR Software (Frigate/ZoneMinder).

- Network Management tools.

- Reliability: ZFS file system ensures data integrity and easy snapshots/backups for disaster recovery.